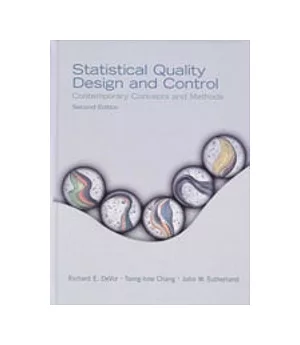

Emphasizing proper methods for data collection, control chart construction and interpretation, and fault diagnosis for process improvement, this text blends statistical process control (SPC) and design of experiments (DOE) concepts and methods for quality design and improvement.

Importance is placed on both the philosophical/conceptual underpinnings and the techniques and methods of SPC and DOE. The concepts and methods of Taguchi for quality design are combined with more traditional experimental design methods to promote the importance of viewing quality from an engineering design perspective.

Features

1.Features a blend of statistical process control (SPC) and design of experiments (DOE) concepts and methods for quality design and improvement.

2.Places particularly strong emphasis on proper methods for data collection, control chart construction and interpretation, and fault diagnosis for process improvement.

3.Provides careful explanations, using actual cases, of the relationship between quality intent through engineering design and its realization through manufacture.

4.Computer workshops and the associated software provided with the book allow readers to simulate processes and apply the methods presented to solve problems.

New To This Edition

1.Several new chapters:

Design and Analysis of Engineering Tolerances

Design and Analysis of Simple Comparative Experiments

Response Surface Methodology.

2.An updated perspective on the state of quality since 1990.

3. New case studies

4. Three new DOE computer workshops on factorial design, fractional factorial design, and response surface methodology.

5.40% new or revised homework problems

推薦序 品質就是企業的格局" onerror="this.src='/themes/default/images/no_img.jpg';">

推薦序 品質就是企業的格局" onerror="this.src='/themes/default/images/no_img.jpg';">