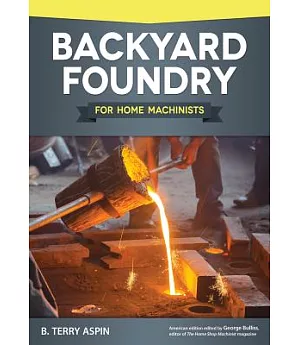

For people who are experienced working with metal, Aspin explains how to set up and operate a home foundry for melting metal, pouring it into a cavity of damp sand, and letting it cool to the

inside shape of the cavity. The seemingly simple process, which has been used for thousands of years, quickly becomes complex, he says, most particularly in assuring that the mold is the

desired shape and holds that shape during pouring and cooling. He covers patterns; plate patterns; cores, core boxes and core making; casting locomotive cylinders; wheels; metal, the furnace,

and melting; and a solid fuel furnace. Annotation ©2015 Ringgold, Inc., Portland, OR (protoview.com)